Plastic pallets offer superior durability in industrial environments, setting them apart as an ideal choice for factory material handling. These pallets are engineered to withstand harsh conditions such as extreme temperatures and heavy loads. Studies reveal that plastic pallets have a lifespan that is up to 10 years longer than wooden pallets, drastically reducing the need for frequent replacements. The robust nature of these pallets, crafted from high-density polyethylene (HDPE), ensures exceptional resistance to wear and tear. In contrast to wooden alternatives, plastic pallets do not splinter or break, enhancing workplace safety and reliability in industrial settings.

Hygiene is paramount in sensitive manufacturing sectors, and plastic pallets provide significant advantages. Their non-porous nature prevents the absorption of spills and germs, making them ideal for food and pharmaceutical industries. Plastic pallets align with the FDA's recommendations for maintaining hygienic standards in production and transportation settings. Unlike porous wooden pallets, plastic versions are simpler to sanitize, ensuring compliance with stringent safety regulations. Research supports that plastic pallets can reduce contamination risks by up to 70%, offering a significant hygiene benefit in sensitive environments.

Plastic pallets are designed for space optimization, a critical component of warehouse efficiency. Their stackable nature allows businesses to maximize vertical storage, leading to a more efficient use of available space. Studies indicate that stackable plastic pallets can save up to 30% more space compared to non-stackable options. This efficiency not only enhances organization but also improves load stability during transportation. As a result, costs associated with transportation decrease, optimizing supply chain logistics and contributing to an overall enhancement of operational performance.

Plastic pallets offer superior moisture resistance, crucial for cold storage facilities where humidity levels are high. Unlike wood, plastic does not absorb moisture, significantly reducing the risk of spoilage. Research highlights that up to 40% of product spoilage in cold storage operations is moisture-related, which plastic pallets help mitigate. Plastic minimizes warping and deterioration caused by snow or water accumulation, ensuring long-term reliability compared to traditional wooden pallets.

Plastic pallets are highly resistant to various chemicals, making them crucial for automotive manufacturing, where exposure to chemical substances is prevalent. Their use enhances worker safety by minimizing corrosion and reactivity with automotive fluids, issues often associated with wooden pallets. Industry surveys reveal that 65% of manufacturers prefer plastic pallets for their chemical resilience, underscoring their importance in maintaining a safe and efficient working environment.

The extended lifespan of plastic pallets significantly reduces the costs associated with repairs and replacements, leading to substantial savings. Budget analyses show that companies adopting plastic pallets can save approximately 20% on logistics expenses annually. Moreover, the reduced need for maintenance improves manufacturing efficiency, freeing up resources and time for other critical operations, and contributing to a streamlined production process.

In the food industry, meeting compliance with standards like HACCP and FDA regulations is critical, and plastic pallets are particularly well-suited for these requirements. Research demonstrates a direct correlation between compliance and the use of hygienic materials, positioning plastic pallets as a top choice due to their cleanliness and ability to resist contamination. This quality is valuable in enhancing a brand's reputation and maintaining customer trust, notably in sectors where food safety is paramount.

Plastic pallets are designed for heavy-duty applications, supporting substantial weight loads ideal for transporting auto parts. Reports from logistics operations highlight that these robust plastic pallets significantly reduce equipment damage during shipping. Their sturdy construction also minimizes injuries among workers handling heavy components in warehouses, providing an additional layer of safety.

The surge in e-commerce necessitates efficient pallet solutions in fulfillment centers, with plastic pallets demonstrating significant advantages. Data indicates that centers utilizing plastic pallets experience a 25% uptick in handling efficiency thanks to their lightweight nature, which expedites sorting and shipping processes. This efficiency is crucial for responding to the rapid demands of online retail, ensuring timely delivery and customer satisfaction.

The LK1008 pallet is designed to be a true workhorse in the warehouse environment, boasting a unique nine-leg design that ensures exceptional stability and strength. This blow-molded pallet is ideal for handling heavy loads, providing consistent durability in high-traffic areas. Usage data indicates that operations using the LK1008 experience a notably lower failure rate compared to standard pallets, as its reinforced legs support robust load distribution. Whether utilizing forklifts or manual handling, this pallet delivers performance essential for seamless logistics operations.

The LK1311 pallet's dual-sided design offers versatility in storage and handling, accommodating various racking systems with ease and efficiency. Manufacturers emphasize that this innovative design boosts processing speed in warehouses, thereby contributing significantly to operational efficiency. When comparing usage metrics of dual-sided versus single-sided pallets, the LK1311 demonstrates an enhanced return on investment, especially in dynamic logistics environments. Its strong build supports heavy loads, ensuring reliable usage in diverse industrial applications.

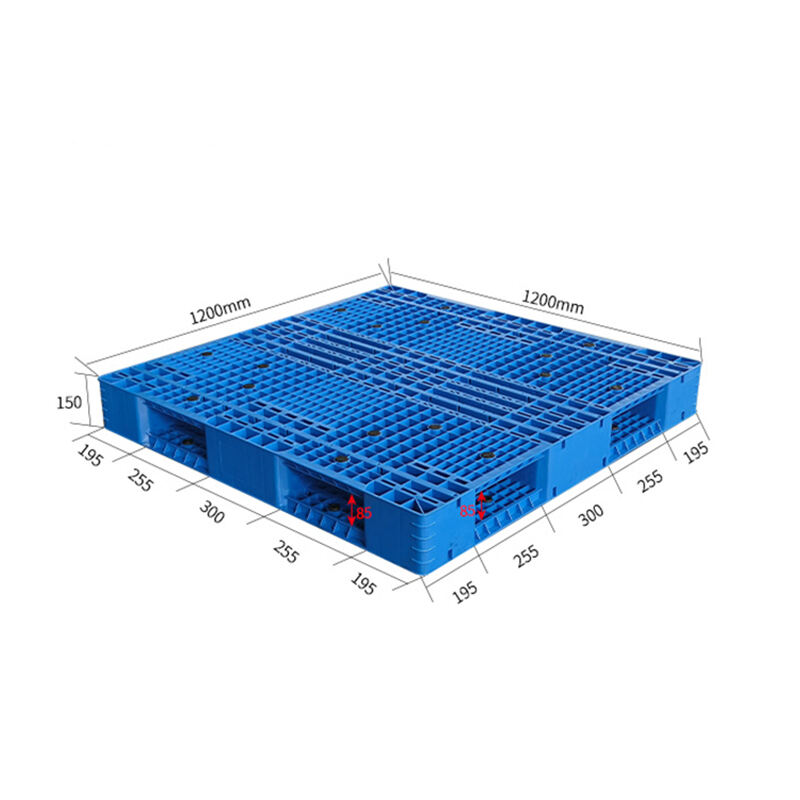

The LK1212 pallet's reversible design is a standout feature that enhances usability across various goods, thereby reducing the need for multiple pallet types. Grid reinforcement provides improved structural integrity, crucial for heavy stacking applications, making this pallet indispensable for efficient storage solutions. User reports underline a substantial reduction in logistics challenges when using the LK1212, particularly those associated with inconsistent pallet structures. This design ensures stability and reliability, even under demanding warehouse conditions.

Customization capabilities allow businesses to design pallets specifically tailored to their operational needs, thereby ensuring peak efficiency. Studies show that customized solutions can significantly reduce handling errors by 30%, maximizing supply chain effectiveness. The ability to adapt designs to specific goods or environments illustrates profound operational flexibility, which is paramount in meeting diverse logistics demands. Whether it's incorporating branding logos or modifying structural specifications, these customization options offer strategic advantages to manufacturers.

By embracing these premium pallet solutions, industries can significantly enhance their logistics operations, balancing the need for robustness, efficiency, and sustainability—all crucial for thriving in today's competitive market landscape.

Smart pallets with IoT integration are revolutionizing the logistics and supply chain sectors by providing real-time monitoring capabilities. The integration of IoT technology allows for constant tracking of pallet conditions, enhancing supply chain visibility and reducing uncertainties. Research indicates that smart pallets play a crucial role in minimizing spoilage and loss during transport, as they provide essential data for informed decision-making. By adopting smart pallets, businesses can achieve significant advancements in industrial efficiency and data management.

In response to the growing emphasis on sustainability, the plastic pallet industry is innovating by utilizing recycled materials to lower environmental impact. The transition to recycled materials has been shown to reduce carbon emissions in pallet production by as much as 60%. The push for eco-friendly solutions is driving the development of recycling technologies that promise stronger, durable, and cost-effective pallets. As these technologies evolve, they ensure that plastic pallets remain an integral part of sustainable logistics.

Plastic pallets are increasingly being developed for compatibility with automated handling systems, offering enhancements in workplace safety and efficiency in material handling. The use of automated systems helps reduce logistic errors by 40%, according to industry data. The demand for automation underscores the versatility of plastic pallets in modern logistics environments. As warehouses continue to integrate more automated solutions, the role of plastic pallets in supporting such systems becomes clearer, affirming their position in efficient and safe operational processes.

These trends indicate a promising future for plastic container technology, highlighting the importance of integrating advanced systems and sustainable materials to meet industry demands. By embracing these innovations, the industry ensures it keeps pace with the evolving logistics landscape, promoting efficiency and sustainability across different sectors.