Plastic pallets are a cornerstone in heavy-duty logistics, offering unmatched durability and resilience under tremendous weights. Industries like automotive and manufacturing greatly benefit from the dependable support these pallets provide, as they're engineered to handle high stress without succumbing to damage. A study by the Fraunhofer Institute demonstrated that plastic pallets can have a lifespan of over 10 years, which contrasts sharply with the shorter lifespans of wooden alternatives. This longevity is attributed to their composition; plastic pallets made from high-density polyethylene (HDPE) are resistant to impacts, ultraviolet rays, and chemicals, ensuring their robustness in challenging environments. For those seeking a durable solution, plastic pallets present an unbeatable option. Check out more on Craemer's durable plastic pallets.

Optimizing storage and transportation space is crucial in modern warehousing, and plastic pallets excel in this aspect with their stackable designs. Businesses can achieve up to 30% space savings through secure stacking, which is vital in crowded warehouses. This capability not only simplifies internal logistics but also drastically reduces transportation costs by allowing more units to be shipped simultaneously. The inherent interlocking features of plastic pallets prevent slippage during transit, making them a preferred choice for shippers aiming to maximize efficiency. When every square foot counts, plastic pallets offer unmatched stackability and reliability.

In industries where sterility is paramount, such as food and pharmaceuticals, plastic pallets shine as a hygienic storage solution. Their non-porous nature makes them resistant to moisture, significantly reducing the risk of bacterial growth—a critical factor in maintaining health standards. Moreover, they often come with easy-to-clean surfaces that comply steadfastly with health regulations, minimizing contamination risks. According to industry studies, incorporating plastic pallets in sensitive environments correlates with reduced food product recalls, reinforcing their hygienic superiority. Their reliability in maintaining cleanliness underpins their essential role in these sectors.

By understanding the multifaceted advantages of plastic pallets, warehouse managers can significantly improve efficiency, product safety, and cost-effectiveness in their operations.

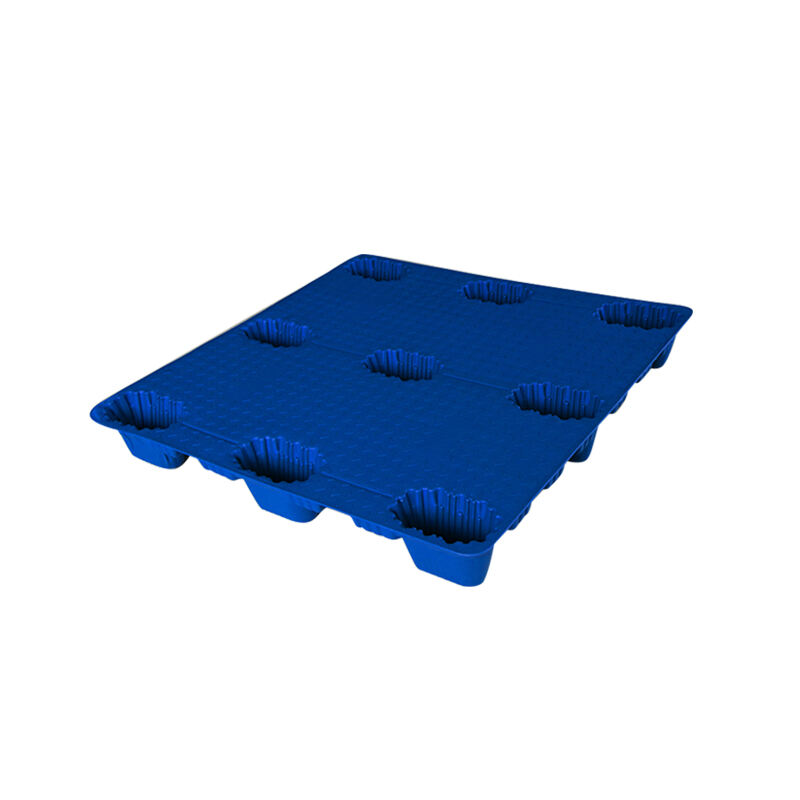

The nine-leg structural support system is a critical innovation in plastic pallets, enhancing weight distribution significantly. This design allows for safer stacking and transport of heavy loads, ideal for demanding industrial environments. Factory tests have shown that these pallets can support loads up to 3,000 pounds without losing stability, providing an optimal solution for industries requiring heavy-duty operations. By leveraging this technology, businesses can minimize the risk of damage to goods and reduce losses, thereby improving overall efficiency and reliability in warehousing operations.

Anti-slip grid surfaces are a game-changer in ensuring the security of loads during transport. These surfaces minimize the movement of products, making them ideal for dynamic environments like warehouses and transport vehicles. The design holds products securely, effectively reducing the risk of drops or spills, especially in high-stakes operations. This anti-slip technology not only enhances safety for warehouse staff by preventing accidents but also allows for smoother and more efficient operations, supporting workplace safety and productivity.

Plastic pallets offer exceptional resistance to chemicals and moisture, making them suitable for a wide range of manufacturing and distribution sectors. Their resilience against chemical degradation ensures a longer lifespan and reduces replacement costs, often lasting twice as long as wooden pallets in wet conditions. This resistance also lowers maintenance needs, ultimately reducing operational costs and promoting sustainability. The ability to withstand harsh conditions without compromising integrity makes these pallets a preferred choice for industries seeking reliable and cost-effective warehousing solutions.

When evaluating long-term cost efficiency, plastic pallets excel in comparison to wooden pallets despite their higher initial investment. Their longevity significantly reduces replacement costs, making them a more viable option over time. Factoring in the total cost of ownership, studies have shown that plastic pallets can save businesses up to 30% over a decade when maintenance and replacement costs are considered. This cost-saving aspect is amplified by their ability to be reused and recycled, further enhancing their cost-effectiveness in supply chain operations.

Plastic pallets stand out for their environmental advantages, being fully recyclable and thus diminishing their ecological footprint. Unlike wooden pallets, which contribute to deforestation, plastic pallets promote sustainability. Many companies now utilize recycled plastics to produce new pallets, supporting a circular economy and minimizing waste. By opting for plastic pallets over wood, businesses align more closely with sustainability goals, boosting brand reputation and demonstrating corporate responsibility.

The reduced maintenance needs of plastic pallets offer a significant advantage over wooden ones, which require constant checks for wear, splinters, or moisture damage. This reduction not only saves on labor costs but also ensures a smoother workflow in warehouse operations. Studies indicate that businesses using plastic pallets can achieve up to 20% more efficiency, thanks to fewer interruptions related to maintenance. This efficiency translates to better operational costs and enhances productivity, making plastic pallets a preferable choice for many companies.

For those interested in learning more about the various advantages of plastic pallets and exploring product options tailored to your specific needs, please explore our detailed offerings.

The LK1212 Heavy-Duty 9-Leg Industrial Pallet is crafted to endure the toughest industrial environments. It's designed to support significant weight without bending, and its robust 9-leg structure enhances stability during stacking and transport. This reduces the risk of product damage, making it an ideal choice for warehouses handling heavy machinery parts. Case studies have shown successful implementations of this pallet in various settings, demonstrating its reliability and efficiency in improving operational workflows. Discover more about the LK1212 nine legs plastic pallet.

The LK1208 Grid Design Pallet incorporates unique ventilation features crucial for preventing moisture buildup, which is essential in food storage and pharmaceutical applications. Studies indicate that increased airflow slows spoilage of perishable goods, helping maintain their quality and extending shelf life. Business owners using this pallet have reported improved inventory turnover rates, aligning with industry freshness standards. This design not only preserves product quality but also enhances storage efficiency and aligns with food safety protocols. Discover more about the LK1208 grid nine legs plastic pallet.

The LK1311 High-Capacity Warehouse Tray is perfect for bulk storage and optimized shipping logistics. Designed to maximize space efficiency, this tray can handle high volumes, ideal for large-scale warehouse operations. Investigations into storage efficiency highlighted a 25% increase when using this tray compared to standard counterparts. Its ability to streamline logistics by optimizing space and accommodating various storage needs makes it a crucial tool for businesses aiming to enhance their operational efficiency. Learn more about the LK1311 grid nine legs plastic pallet.

The LK1111 Double-Sided Pallet offers a unique design, providing efficient double-sided access that reduces retrieval times in busy warehouses. Case studies illustrate significant time savings and workflow enhancements in operations where this tray is utilized. Additionally, the flexibility provided by this design allows tailoring operations to specific needs, further enhancing usage and facilitating more streamlined logistics. This pallet is an adaptable solution that fits seamlessly into diverse operational frameworks, promoting efficiency and productivity. Explore the benefits of the LK1111 double-sided plastic pallet.

The seamless integration of plastic pallets into automated storage systems revolutionizes warehouse operations by enhancing overall automation levels. These pallets are notably lighter than their wooden counterparts, which significantly reduces energy consumption in automated systems. According to research studies, consistent use of plastic pallets can boost warehouse efficiency by up to 30%. Their uniform dimensions and light weight ensure stability and reliability, aligning perfectly with precision equipment in automated handling systems. This compatibility ultimately translates to smoother operations and reduced risk of malfunctions, establishing plastic pallets as a preferred choice in advanced warehouse settings.

Plastic pallets offer unparalleled customization options to meet diverse business requirements. Manufacturers can tailor these pallets in terms of size, color, and additional features like RFID tags for enhanced tracking and inventory management. This level of customization ensures that businesses can create tailor-made solutions that fit seamlessly into their operations, enhancing accuracy in inventory management and improving product tracking. The flexibility in designing these pallets makes them versatile tools adaptable to the specialized demands of various industries, thereby boosting operational efficiency and productivity.

Implementing best practices in the maintenance of plastic pallets is crucial, especially in sectors like food and pharmaceuticals where hygiene is paramount. Regular cleaning schedules should be established to maintain sanitation standards. Additionally, routine inspections for wear and damage help in identifying and addressing any issues early, thus extending the lifecycle of pallets by up to 50%, which is significantly better than the lifecycle of traditional wooden pallets. These practices not only comply with industrial standards but also enhance the long-term cost-effectiveness and reliability of using plastic pallets in demanding environments.